Indicators on Roof Spandrel Panels You Should Know

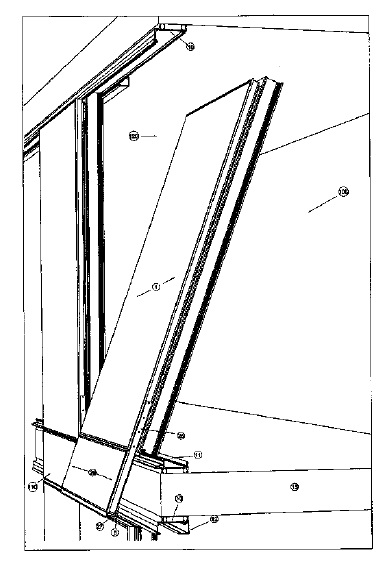

By recognizing surface temperatures, Pie has the ability to establish under which conditions condensation will occur, as well as identify shift points at which condensation will certainly not develop, making it less complicated to anticipate and also remediate - curtain wall spandrel panel detail. In enhancement, various setups can be modeled to make the most of interior surface temperature levels. Mounting back pans into the spandrel infill glazing pocket, which are vented to the exterior with insulation outboard of the frying pan, advertises raised indoor surface temperatures with the added advantage of minimizing warmth transfer through the spandrel infill.

It is possible to make the most of interior surface area temperature levels by eliminating the use of insulation at the spandrel infill place. Bear in mind if you design without insulation at spandrel infill places, there will be a better power loss through the assembly and therefore larger A/C warm loads. At Pie, we can help you each action of the means, whether you lately found condensation and are looking for removal as well as monitoring remedies, or whether you are creating a building as well as objective to lessen the possibility for condensation at spandrel infill locations.

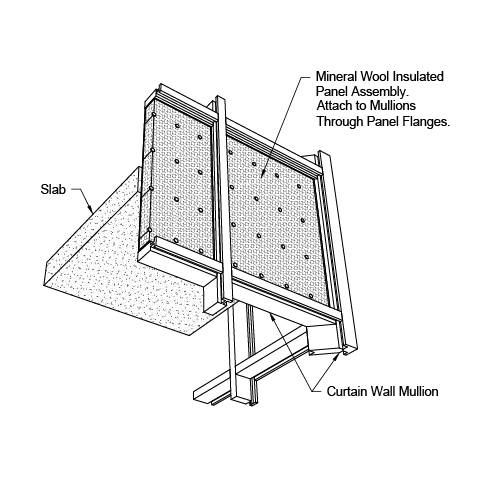

Boost R-Values Without Compromising Design! Glazing infill panels are designed to be 'polished' right into an aluminum home window system instead of glass. They use many advantages to architects and structure owners looking for economical and also cosmetically pleasing options for their buildings. Protected panels contain 3 different layers- an inflexible insulation core sandwiched between an ended up concrete face and also back.

Made use of as a home window replacement, Synstone infill panels enhance the thermal efficiency of window openings. This reduces the cost of ownership by enabling financial savings on home heating and cooling. Synstone infill panels contain non-asbestos glass fibre reinforced concrete faces with foam core insulation. Synstone infill panels can be made to R= 24 insulation worth.

The Greatest Guide To Insulated Spandrel Panel Detail

In traditional structure, the term "describes the roughly triangular room or surface area that is found between a bent number and also a rectangle-shaped boundary. It is thought to stem from from the Old French word 'spandre', meaning to spread. Such can be found in a number of circumstances: Much more lately, the term 'spandrel panel' has been used to describe built triangular panels made use of in roof covering construction to separate areas under the roof, or to finish the gable end of a roofing.

The term spandrel panel may likewise be used to refer to cladding panels that load the area above the head of a window on one flooring as well as listed below the cill of the home window on the next flooring on her explanation high-rise buildings. These panel glass shipment panels hide the flooring structure. If they are made from nontransparent or transparent glass, this may be described as spandrel glass.

It suggests that; "Spandrel panels can be attended to both aesthetic and practical purposes. Like the remainder of the exterior wall, the panels are normally called for to satisfy acoustic, thermal, moisture, and fire performance needs. nhbc spandrel panels. Such panels are not normally load bearing yet are commonly developed to account for wind loading...

Where there is no details concerning the panel or there is unpredictability, it will certainly be essential to explore the panel make-up by sample screening." Ref https://www.gov. gable spandrel panel.uk/government/publications/advice-for-building-owners-on-spandrel-panelswindow-panelsinfill-panels-on-external-walls NB The term spandrel light beam describes an exterior light beam that expands from one column to an additional, lugging an exterior wall lots.

Glaz-Tech Industries presents GlazeGuard 250WR as well as GlazeGuard1000 WR infill panels to further provide added building services for shop and home window systems. Its long lasting and also eye-catching design contributes with shop applications and also shielded devices. Glaz-Tech's infill panels use a number of architectural benefits: GlazeGuard WR panels are highly reliable against moisture breach as well as likewise suitable for installment because of its light-weight layout.

Unknown Facts About Glazed Spandrel Panel

With several different structures and surface choices, GlazeGuard can supply an economical alternative to various other polishing remedies while still supplying aesthetic passion and value. Little or no maintenance is required and most oil, dirt, oil and also various other foreign material can be conveniently cleansed from the surface area. Glaz-Tech supplies Metallic Silver, Shasta White and Classic Bronze.

Part Standard (in) Metric (mm) Prefinished Textured Light Weight Aluminum Skins.010".254 mm Prefinished Smooth Light weight aluminum Skins.024".609 mm High Density Polypropylene Core 1/4" 6.00 mm Home Requirement (in) Metric (mm) Panel Weight.72 pounds/ ft 3.51 kg/ m Nominal Thickness 1/4" 6mm GlazeGuard 1000 WR is a composite panel for use as a polishing infill made by laminating flooring two prefinished light weight aluminum skins to substrates of high density polypropylene.